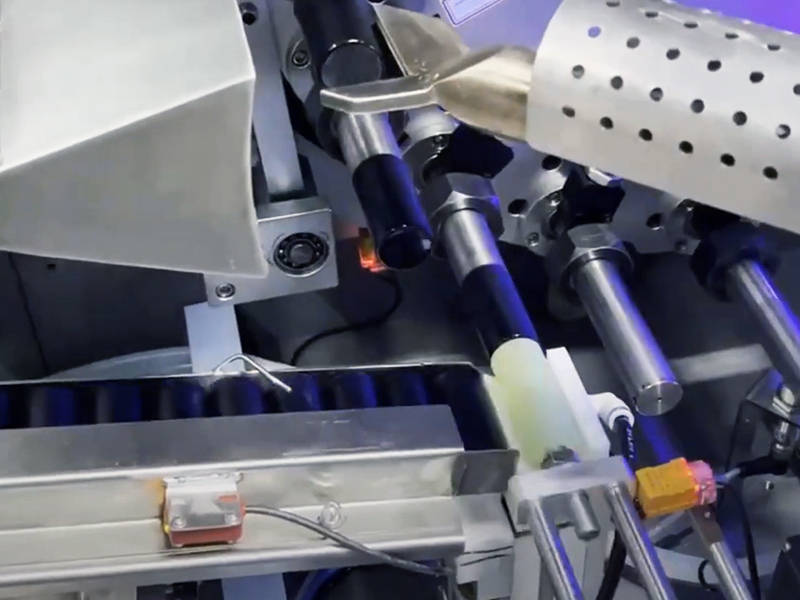

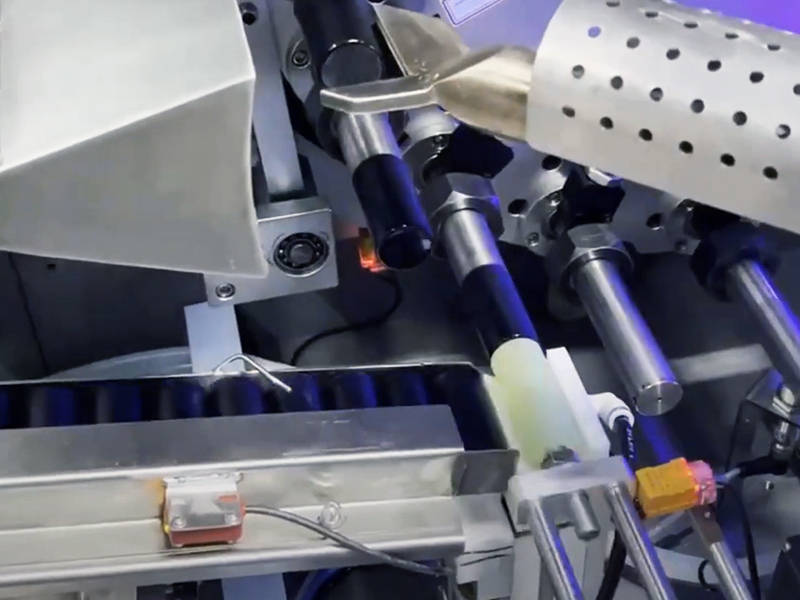

With the continuous development of technology, automation technology has been widely applied in various industries. In the field of automation, we often hear two terms: non-standard automation and standard automation. Although they both aim to improve production efficiency and quality, there are significant differences in practice. This article will explore the differences between non-standard automation and standard automation based on keywords.

Explore the difference between non-standard automation and standard automation

Explore the difference between non-standard automation and standard automation

1. Flexibility and Customization:

-Non standard automation: Non standard automation places more emphasis on flexibility and customization. It is suitable for situations with complex production lines and significant product differences. Non standard automation systems can be adjusted and customized according to the needs of different products to meet diverse production requirements.

-Standard automation: In contrast, standard automation is more inclined towards mass production and large-scale production. Its design tends to invest a large amount of money at once to establish an efficient production line, suitable for producing relatively single and large-scale products.

2. Cost and Investment:

-Non standard automation: Due to the need for customization and adjustment for different products, non-standard automation systems typically require higher investment costs. But with the continuous development and maturity of technology, its operating costs gradually decrease, and it has high flexibility and adaptability.

-Standard automation: The initial investment in standard automation is usually high, but due to its relatively stable production process, the operating costs are relatively low. In large-scale production, standard automation can produce products at lower unit costs.

3. Scope of application:

-Non standard automation: Non standard automation is more suitable for scenarios that require rapid response to market changes and flexible adjustment of production lines. Especially in customized products and small batch production, non-standard automation has obvious advantages.

-Standard automation: Standard automation is more suitable for stable production needs and large-scale production. It can achieve high production efficiency and consistent product quality, suitable for highly repetitive production tasks.

4. Technical requirements and complexity:

-Non standard automation: Due to the need for customization and adjustment for different products, the technical requirements for non-standard automation systems are high, and there may be some complexity in the implementation process. Professional engineers and technical teams are needed for design, debugging, and maintenance.

-Standard automation: In contrast, the technical requirements for standard automation systems are relatively low because their production processes are relatively fixed and stable. Once established, standard automation systems are usually easier to operate and maintain.

In practical applications, enterprises need to choose appropriate automation methods based on their own production needs, product characteristics, and market positioning. Sometimes, a combination of non-standard automation and standard automation can be adopted to fully leverage their respective advantages and achieve more efficient production and management.

Explore the difference between non-standard automation and standard automation

Explore the difference between non-standard automation and standard automation